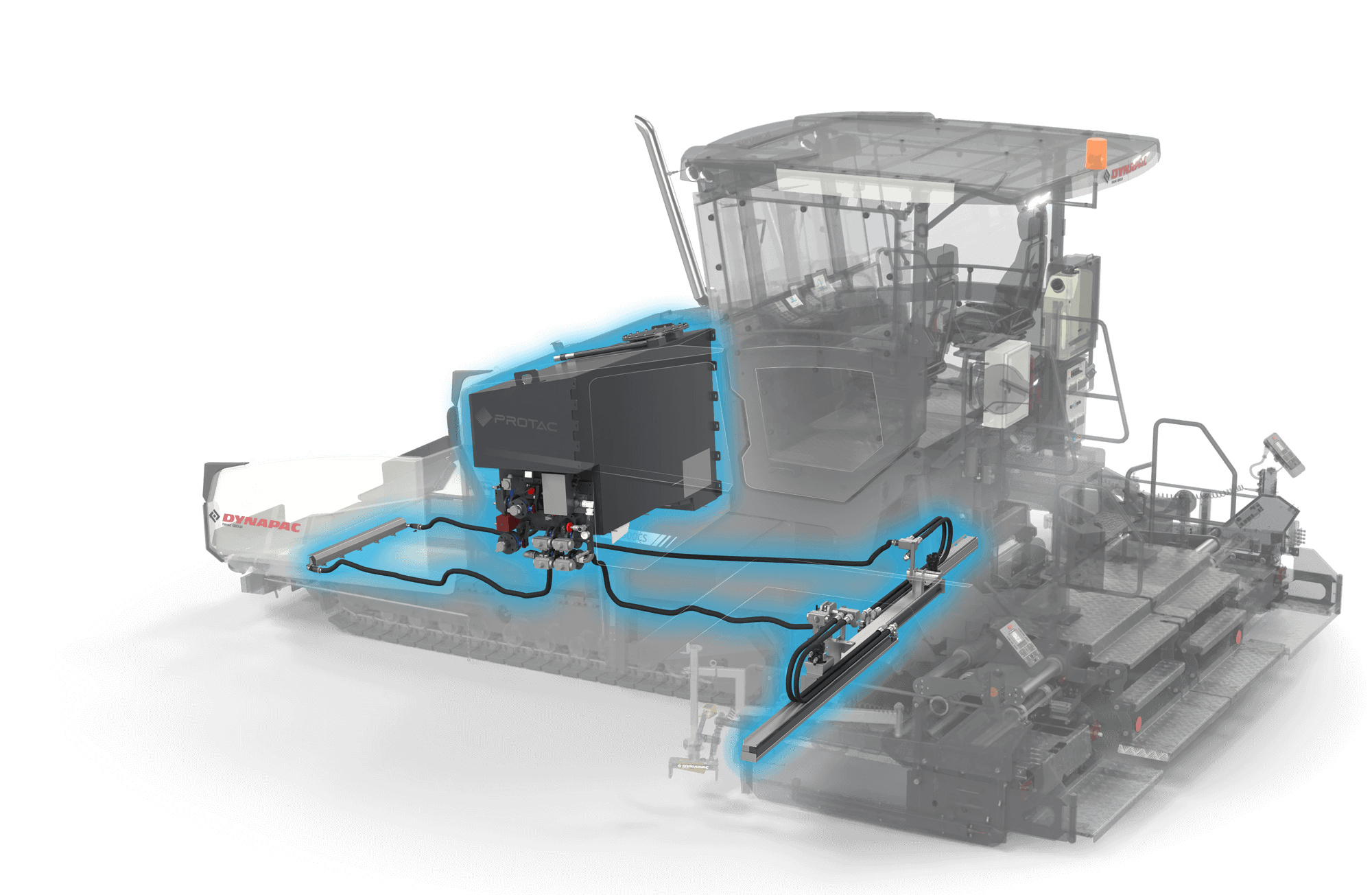

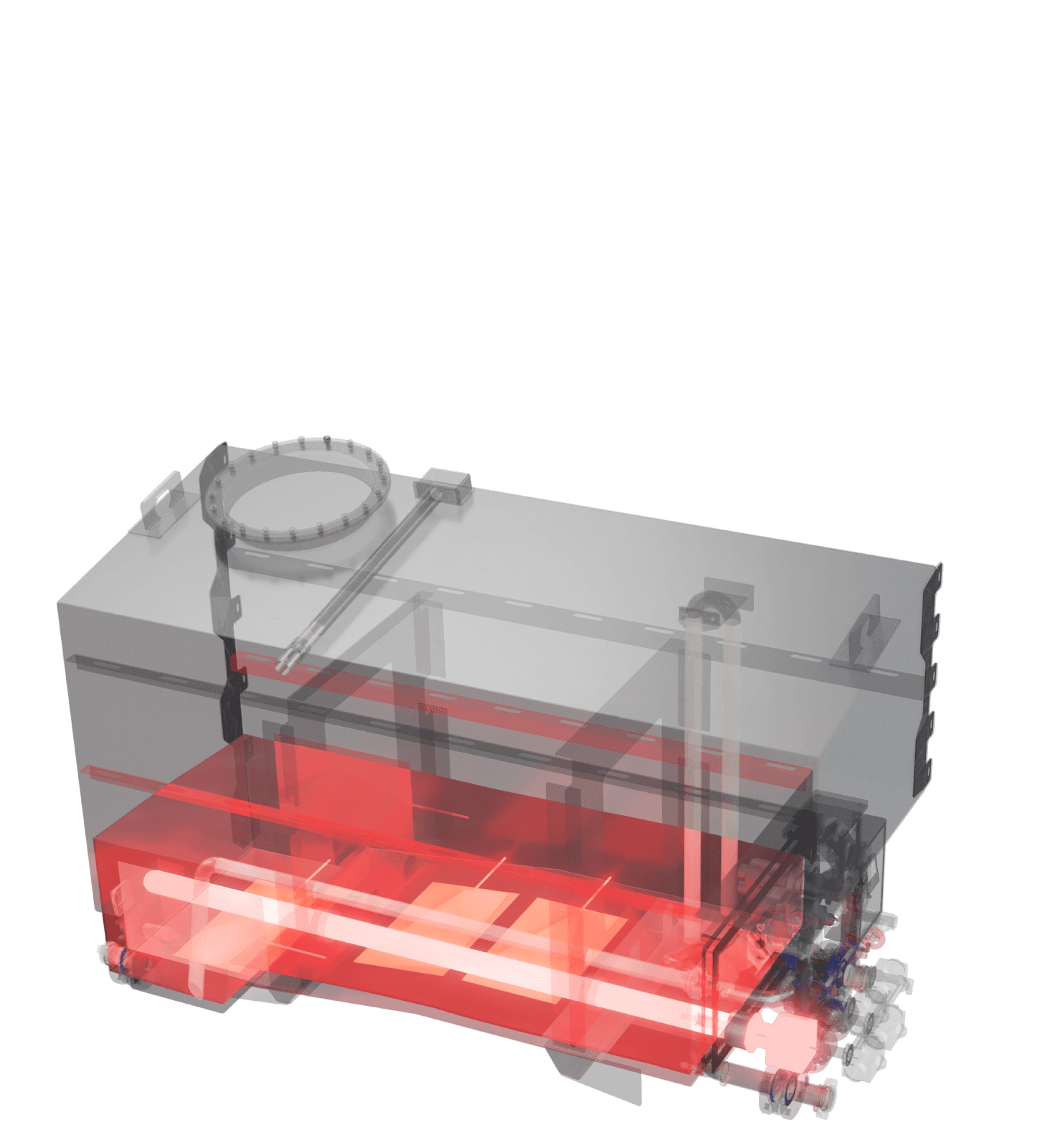

The Dynapac Spraypaver PROTAC brings two processes together in one machine: paving and spraying. With the Dynapac PROTAC everything is seamlessly integrated into the system and easily activated. The sliding bar concept with symmetric hoses ensures a uniform emulsion mat.

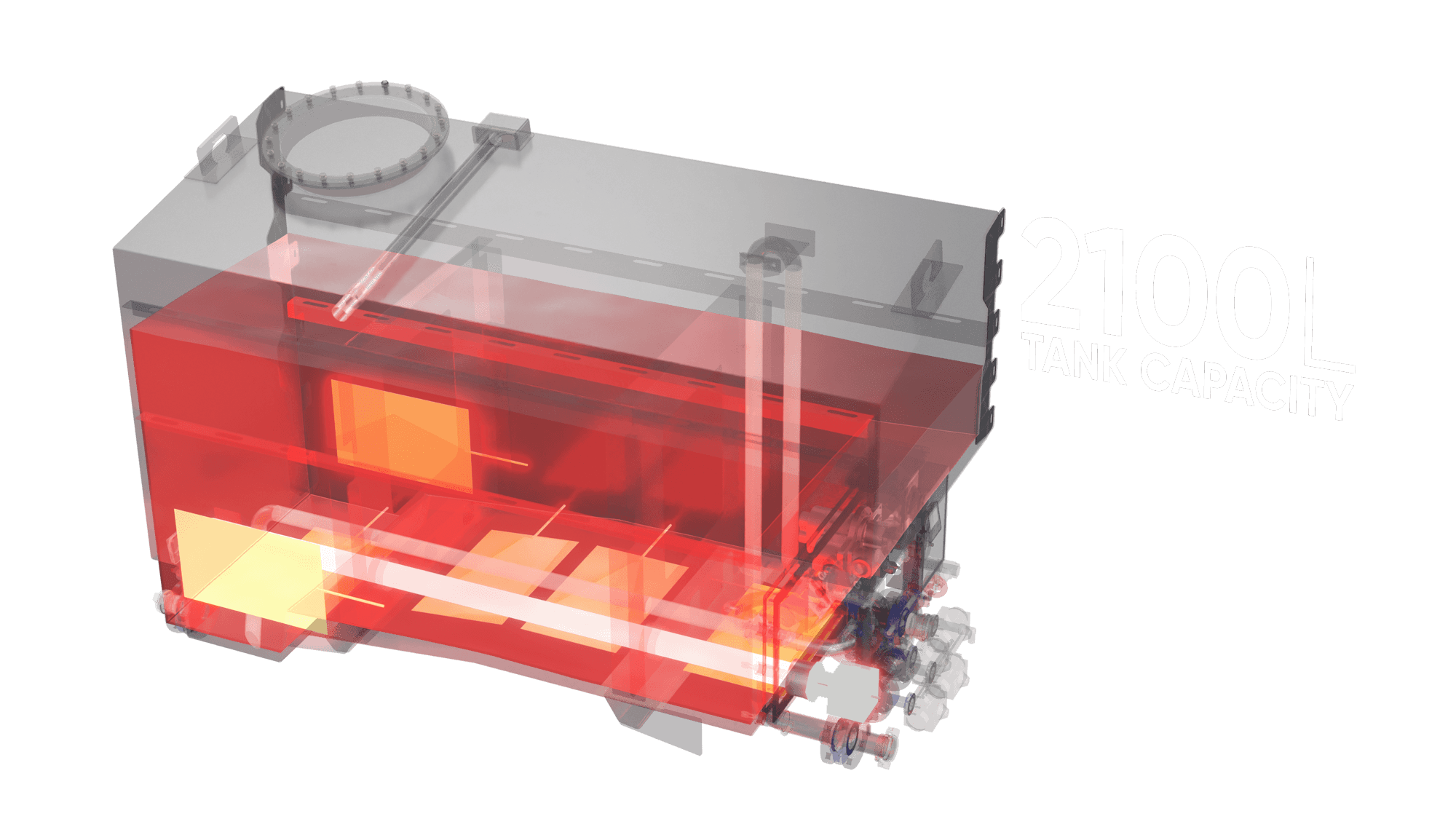

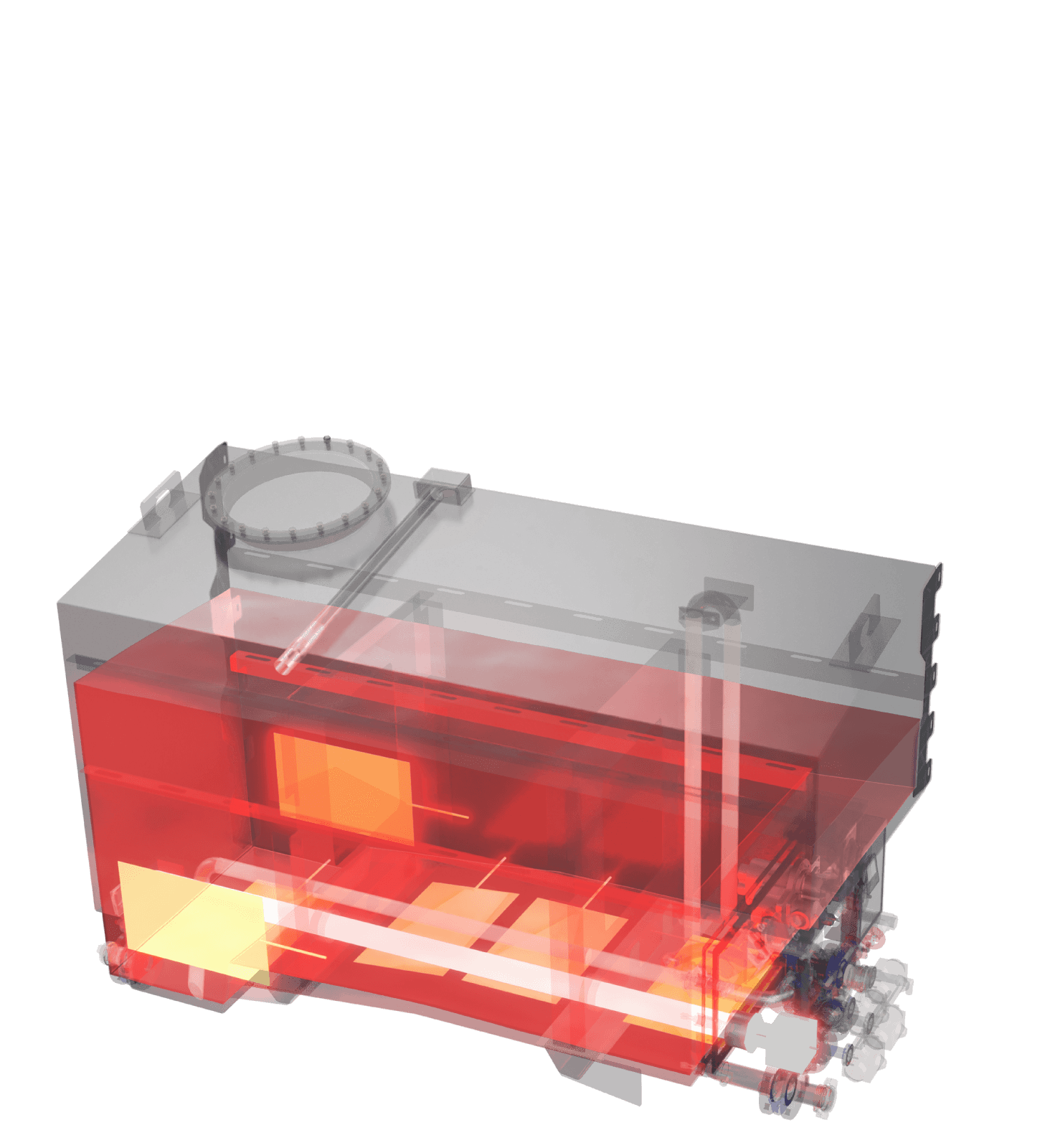

Due to the smart heating concept with mats and heating rod the emulsion is heated up in a gentle and efficient way for the highest quality. From 100l up to 2100l.

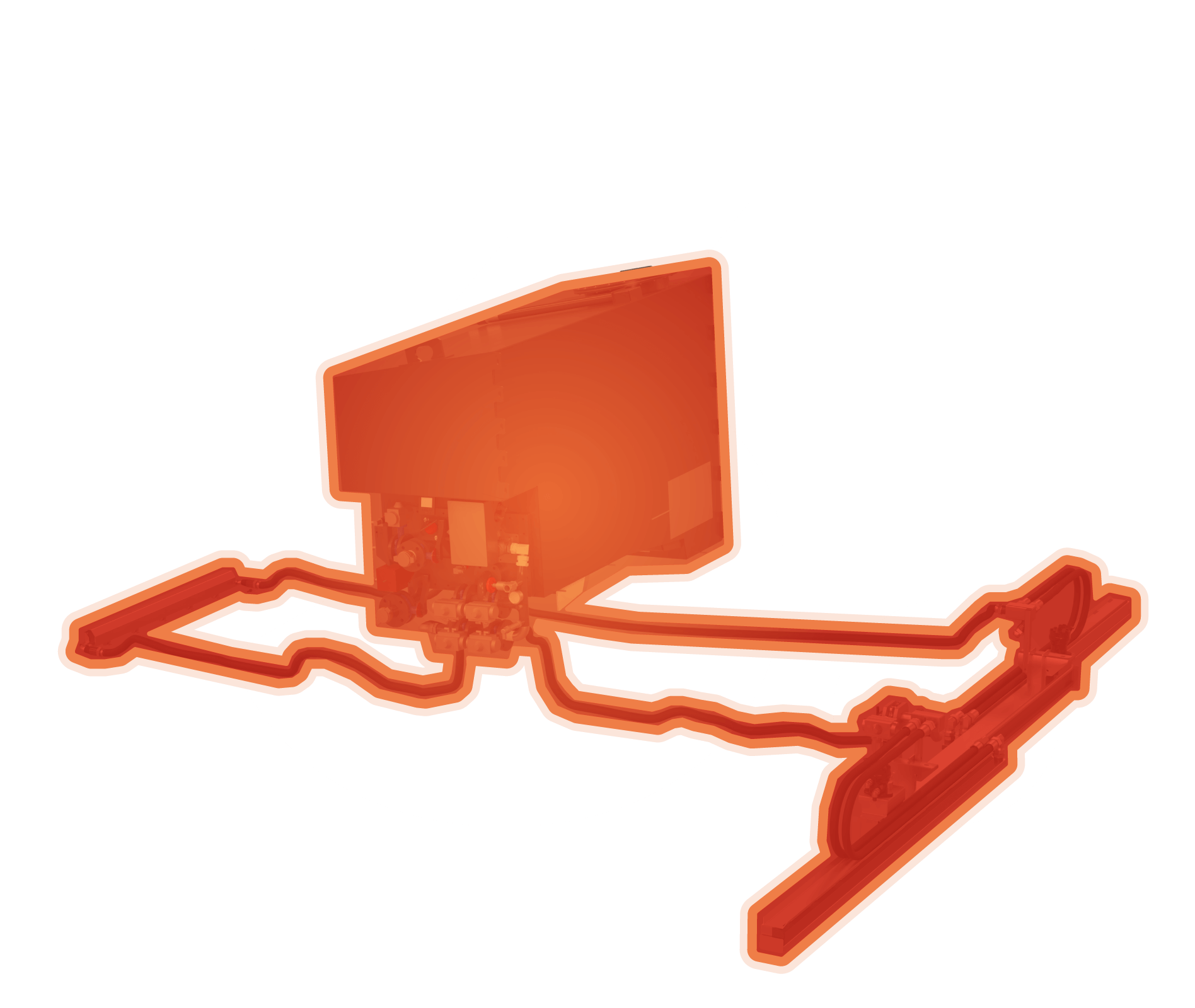

Paver set up with integrated tank and sliding bars up to

< – – 6,5m on V5100TVE Screed – – >

< – – 7.0m on V6000TVE Screed – – >

laid-back

Refilling

Insulated emulsion tank, which can hold up to 2100 liters of emulsion and is equipped with a filling point and display on each side. For easy and safe refilling.

Smart and powerful heating

Stage 3: 18 kW

between 2100L

and 700L

Stage 2: 15 kW

between 700L

and 300L

Stage 1: 3 kW

between 300L

and 100L

3 stage Flow system of emulsion to avoid cracking

1. Heating mats start gentle heating of the emulsion inside the tank.

2. Heating the small spraying circuit to keep the emulsion moving, to avoid cracking, and keep the emulsion quality on a high level.

3. Heating of the large symmetric circuit for even heat distribution and ready for spraying modus.

A spray bar, which adapts to your needs

The spray bars automatically follow the screed movement, thus ensuring optimum uniformity and control. If necessary, the screed operator can retract or extend the spray bars regardless of the screed position and, the spray bar can be preset to a larger or smaller working width

Easy and fail-safe cleaning at the end of a work shift with compressed air and cleaning fluid. Multiple modes allow to clean system and nozzles based on needs and regulations. Self-cleaning function, when the machine is turned off after spraying.

dynapac protac

spraying experts

are back